Accidents happen, particularly in working environments dealing with chemicals, oils, and other hazardous materials. That’s where spill kits come in. Spill kits are the first step in emergency and industrial spill response. In essence, these kits are meant to aid you in cleaning up spills quickly and safely, protecting your employees, property, and environment. We’ll cover everything you need to know about spill kits: from why you need to get them to which industries and of course proper training.

Why You Need Spill Kits

Here is why it’s super important to have spill kits at your place of business: First, for safety reasons. A spill kit keeps employees safe from exposure to all types of hazardous materials. This is very important for maintaining a safe work environment and keeping your most valuable asset—your workforce—protected.

An important advantage associated with the readiness of a spill kit is prompt response. When a spill has occurred, literally every second counts. The spill kit enables you to respond quickly and thus stop and clean up the spill before it spreads out. This quick response can reduce the potential impact of a spill quite significantly and prevent it from reaching a larger and more dangerous state.

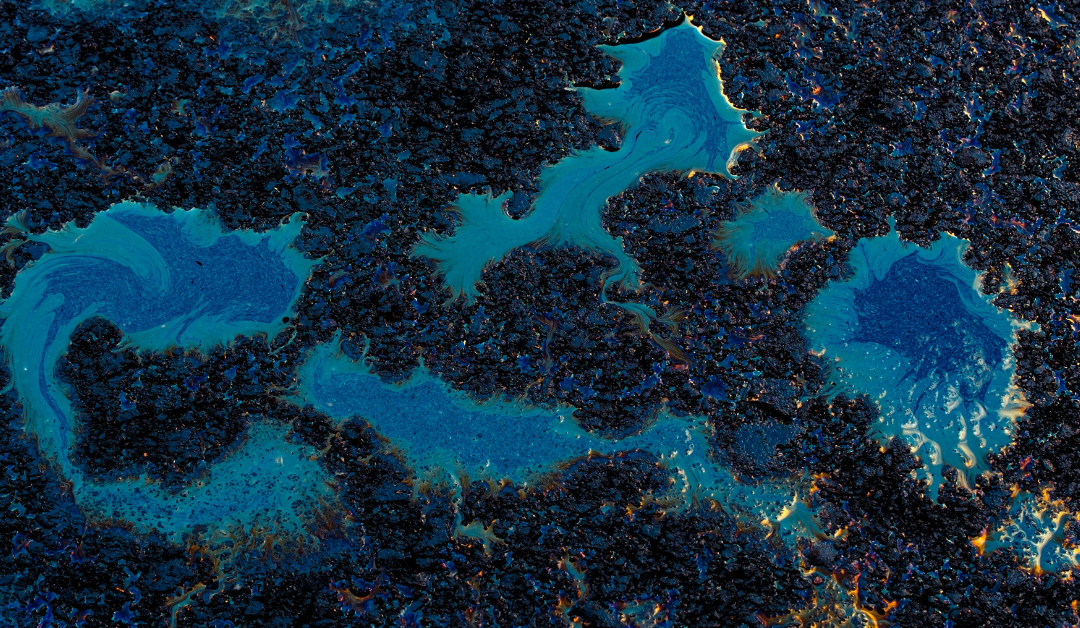

Another major reason for having spill kits on standby is the issue of environmental conservation. Proper use of spill kits means that hazardous materials will never make it into the environment to cause adverse damage. This, therefore, is very important to those businesses that deal with chemicals and other hazardous substances, to prevent contamination of the soil, water sources, and local ecosystem.

Other critical factors include legal conformance. So many industries have legislative laws enforcing a business to keep a spill kit with proper response procedures in place. Having proper spill kits ensures your business complies with them, averting possible fines or potential legal problems.

Finally, spill kits will save you money. Fast action in the case of a spill will prevent damage to valuable equipment and avoid huge clean-up operations. Avoidance of large-scale damage and expensive downtime can be possible through prompt containment and cleanup of spills that might bring far more extensive remediation efforts with them if they had time to spread.

Industries that need to use Spill Kits

Although spill kits are helpful and can be used in almost any work environment, some industries would find them more needed for environmental compliance reasons. Some of these industries include:

- Manufacturing facilities

- Auto repair shops

- Test labs

- Hospitals and other healthcare

- Construction and Demolition sites

- Warehousing and storage

- Oil and gas

- Chemical and petrochemical plants

- Transportation and logistics company

For companies that operate with the handling of liquids or chemical, there is an excellent advantage to using spill kits.

Kinds of Spill Kits

Here are various kinds of spill kits administered to respond to several products.

- General Purpose Spill Kits- Designed for general uses, general spill kits are all-purpose kits responding to various kinds of spills – right from water-based to oils and several chemicals.

- Chemical Spill Kits: In case of a hazardous chemical spill, these kits contain materials that can neutralize or absorb a great variety of chemicals that are being spilled.

- Oil and Fuel Spill Kits: In the case of oil and gasoline spills, flammable liquids require this calcium type of kit to mop up a spill.

- Biohazard Spill Kits: These are the type of spill kits that are made use of in hospitals and health amenities to deal with potentially infectious materials such as body fluids. It is for safe pick-up of body fluids or any other infected materials.

- Typical Spill Kit Contents

Besides the type of spill kit, the contents in them are :

- Absorbent materials — pads, socks or loose absorbents

- Personal protection — gloves, goggles, and sometimes protective suits

- Containment — booms or barriers

- Disposal bags

- Cleaning — brooms, dustpans, or scoops

- Instructions on how to use them

The actual contents may differ depending upon the nature of the spill kit and the types of substances it is designed to handle.

How to Get Spill Kits

Getting spill kits for your work location is easy:

- Assess Your Needs: Identify what type of spills you can have and how much absorbent capacity you may need.

- Choose the Right Kit: With your assessment, you can choose the right spill kit and size to use.

- Buy from Reliable Suppliers: Be sure to purchase from reputable suppliers that will be able to sell you good kits with quality materials and also help you with selection.

- Custom Kits: Some suppliers can also offer custom spill kits.

- Retain and Maintain: Be sure to check your spill kits on a regular basis and restock items that may be past their expiration, damaged, or have been utilized in an event.

Spill and Spill Kit Training at Keystone

Spill The presence of spill kits is just a small part of the answer. Proper training is a key component to have to ensure your team is knowledgeable about the operation of these toolsets at the time of a spill.

- Keystone Spill provides comprehensive training courses to prepare your student/installers to execute the following:

- Spill identification—able to identify kinds of spills and the dangers that surround them.

- Applicability in kit usage—shown how to use a spill kit effectively.

- Protection Steps—protection that can be used during a spill clean up.

- Ecological—understanding the environmental impact of a spill and what to do to curb the damage

- Regulatory—legislation and when and where reporting protocols apply

- Practical—demonstrate the correct procedures for handling simulated spill scenarios.

Then, in a real-life spill, your team will be both confident and able.

The Importance of Spill Kit Maintenance

Ready a spill kit is an effective spill kit. That is why periodic maintenance of your spill kit is imperative for making sure they are ready when you need them.

It is important to review your spill kits on a monthly basis. Check for damaged or missing contents during this review. This frequent inspection shall let you note any irregularity before its becoming a problem in the case of an actual spill event.

If you have had a spill, restore or restock your kit immediately after it has been used. Replace all material items utilized with fresh inventory and then replace them back into the kit. Follow these steps so that your spill kit always remains fully supplied with materials for the next incident.

Finally, remember to check the expiration dates of the contents in your spill kit. This is because some components, such as absorbents, can have an expiry date. Replace these items accordingly to keep your kit effective.

As your workplace will continue to change, so will your spill kit requirements. There should, therefore, be regular reviews of your kits for updating to suit changes in the work environment. This may mean adding new types of absorbents or protective equipment, based on new materials used in the workplace.

Finally, make sure that the spill kit is kept within easy reach. They should be close and available to every employee. You never know when an emergency may arise; sometimes, a single second can really make a difference. So, keep the spill kit at your fingertips.

Be Ready with Spill Kits

A Spill kit is an important part of safety and environmental protection. Ensuring the right kits at hand and proper training of the team for their use can provide for just-in-time, correct reactions, which significantly reduce the risks in view of spills and damage.

Remember, the key to a good response to spills is preparation. Invest in a quality spill kit, maintain them in good condition, and conduct frequent training exercises. With these steps, you’ll be well on your way toward developing an effective response to any spill situation that may occur at your workplace.

Follow us on Facebook to stay up to date with the latest at Keystone Emergency Spill Response.